The use of sulfide leaching was a notable reversal of Hudbay’s previous plan since it purchased the mine complex in 2014. Until last year, Hudbay stated it intended to export raw copper processed into copper concentrate to overseas smelters to begin converting it into metal.

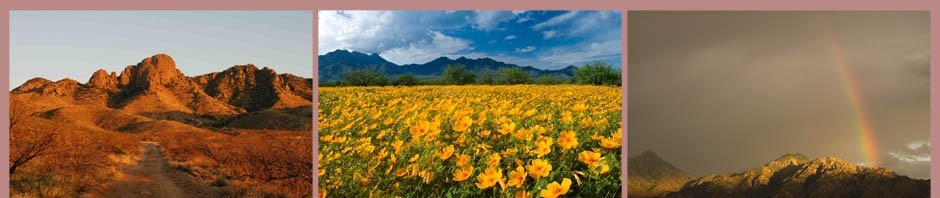

Hudbay’s recent claim it would produce finished copper from sulfide ore is the cornerstone of its marketing plan for the $2.8 billion mine complex that would destroy the northern half of the Santa Rita Mountains about 30 miles south of Tucson and consume about 600,000 acre-feet of groundwater from its Sahuarita well field over the 44-year life of the mine. (An acre-foot of water is equal to 325,851 gallons.)

“The Copper World Complex will support U.S. copper supply through onsite production of copper cathode expected to be sold entirely to domestic customers and reduce energy consumption, GHG and sulfur emissions associated with overseas shipping and processing,” Hudbay claims on its website. (Bold emphasis included by Hudbay.)

But in Aug. 9 comments to stock analysts to discuss the company’s 2nd Quarter financial results, Hudbay CEO Peter Kukielski said the company is still considering the “timeline” of if and when it will install the sulfide leaching technology.

Kukielski told analysts that the company is considering deferring or eliminating the construction of sulfide leaching facilities because it would save between $400 million and $500 million in capital expenses. Kukielski said the company’s decision will be included in an upcoming pre-feasibility study expected to be released by the end of September.

Hudbay has not provided the technical details about the type of sulfide leaching technology under consideration that would allow it to avoid sending copper concentrate to a smelter. Copper contained in sulfide ore bodies, which is by far the dominant ore body at the Copper World/Rosemont complex, is typically processed into copper concentrate at the mine site and then shipped to smelters to begin the refining process to produce useable metal.

Eliminating the sulfide leaching technology raises questions of whether Hudbay will mine oxide ore deposits that require some of the same processing facilities needed to produce finished copper from the sulfide deposits, including a $250 million solvent extraction-electrowinning plant.

Under Hudbay’s current plan, sulfide leaching technology would be used on sulfide ore extracted primarily from the Rosemont pit on the northeast flank of the Santa Rita Mountains and would generate millions of tons of sulfuric acid.

The sulfuric acid would then be applied to crushed copper oxide ore found primarily on the mountain’s west side to extract a copper-laden solution. The oxide ore copper solution would then be mixed with copper solution produced from the sulfide leaching facility and fed into the solvent extraction-electrowinning plant, which would produce nearly 100 percent copper plates.

This is an expensive process that in addition to the solvent extraction-electrowinning plant includes a $45 million oxide ore heap leach facility, a $77 million acid plant that will produce sulfuric acid and an $88 million sulfide concentrate leach plant. The cost of these four facilities comes to $460 million, which falls within the range of the savings Kukielski told analysts would be saved by eliminating sulfide leaching.

This is Kukielski’s second time downplaying Hudbay’s public commitment to produce copper from sulfide ore on-site in comments to stock analysts. “You shouldn’t get stuck on sulfide leaching because it’s simply a plug-and-play option module that’s available to us,” Kukielski told stock analysts in an Aug. 8, 2022, earnings call.

If Hudbay abandons the sulfide leaching process, it will have no choice but to export the copper concentrate because of a lack of U.S. smelting capacity. Domestic copper smelters have closed in the last 20 years because they are major air pollution sources emitting sulfur dioxides and heavy metals. The U.S. has two operating copper smelters, one in Miami, AZ, and the other in Bingham, UT. A third smelter in Hayden, AZ, is not operating because of air pollution compliance issues.

The lack of domestic smelting capacity has resulted in the U.S. exporting 25% of the 1.3 million tons of finished copper and copper concentrate produced by U.S. mines, according to the U.S. Geological Survey’s 2023 copper report. The U.S. is the world’s fifth largest copper producer.

China is by far the leading importer of copper concentrates and operates nine of the 20 largest copper smelters in the world.

HUDBAY IS PROBABLY BACKING AWAY FROM A SUPHIDE LEACH METHOD FOR PROCESSING THE CONCENTRATES ROM THEIR ROSEMONT COPPER PROJECTS IN ORDER TO ATTRACT MORE INTEREST FROM POSSIBLE JOINT VENTURE PARTNERS . THE HAYDEN SMELTER COULD BE UPGRADED BUT THERE IS REALLY NO ” CLEAN WAY ” TO PROCESS COPPER CONCENTRATES INTO COPPER METAL . ELECTROLYTIC METHODS ARE BEING USED IN SOME CASES BUT THEY REQUIRE MAJOR ELECTRICITY AT CONSIDERABLE COST . IF THE ARIZONA GOVERNMENT WAS SMART IT WOULD BUILD A CUSTOM COPPER SMELTER AND REQUIRE ALL MINING COMPANIES TO PROCESS THEIR CONCENTRATES IN A STATE FACILITY . SUCH A FACILITY COULD BE DEEMED A STRATEGIC ASSET WITH LINKS TO FEDERALLY FUNDED DEFENSE PROJECTS . WHAT IS THE TOTAL COST OF REFINED COPPER , INCLUDING FINISHED COPPER PRODUCTS , AS IMPORTED INTO THE US , ON AN ANNUAL BASIS ? WHAT IS THE VALUE OF THE TOTAL COPPER CONCENTRATE EXPORTED FROM THE US ON AN ANNUAL BASIS ? IF COPPER IS DEEMED ESSENTIAL AND STRATEGIC THEN IT MUST BE PROTECTED .

IT IS WORTH POINTING OUT THAT AT LEAST A SIGNIFICANT PORTION OF THE ROSEMONT PROPERTY WAS AT ONE TIME SLATED FOR RESIDENTIAL DEVELOPMENT AND WAS FOR SALE AS SUCH . THE CITY OF TUCSON COULD HAVE PURCHASED THE PROPERTY AND DEVELOPED IT AS A RESIDENTIAL COMMUNITY BUT THEY OPTED OUT . OBVIOUSLY THE TAX PAYERS DID NOT APPROVE AND LEFT THE PROPERTY IN THE HANDS OF REAL ESTATE DEVELOPERS WHO FINALLY SOLD IT TO A MINING SPECULATOR WHO , IN TURN , SOLD IT TO HUDBAY . THE GOVERNMENT AUTHORITIES THAT ISSUED PERMITS , LICENSES , ETC TO HUDBAY ARE FULLY RESPONSIBLE FOR THE SITUATION AS IT EXISTS TODAY REGARDING MINING ACTIVITIES PROPOSED BY HUDBAY . WITHHOLD ANY AND ALL WATER PERMITS FOR MINING AT ROSEMONT AND HUDBAY WILL LEAVE THE SCENE . WATER IS SACRED AND MUST BE TREATED AS SUCH .

Dr. Alan Johnson, my reply to you sir…I am hoping that all people concerned with this mining company Hudbay, can see that the work that they want done, will not happen.

Their plans are falling apart. China’s second largest Property Developer, EVERGRANDE, has filed for Chapter 15 Bankruptcy. (China) who I know is affiliated with this mining

company as of Aug 17th 2023. As you can see, they are talking about cutting corners (sulfide leaching) because they don’t have the money. I have also just read here that Kukielski says that he would not be apposed to incorporating another mine or investors.

What he is really saying is they are broke and can not go forward. They surely won’t be getting any money from Arizona or the United States because we are broke along with them…Well I hope this information is encouraging. I give the Glory to our Heavenly Father for doing the work on our behave. I also want to thank everyone from Save the Scenic Santa Rita’s for all their hard work. Soon Hudbay will pack up and go home.